Systems and Procedures

We understand how important it is for your business to function in an organised and efficient manner. For this to happen your employee's need to understand where they fit into the overall process and what is expected of them. Having well documented systems and procedures gives your staff a point of reference, particularly useful for new starters. They also help you when writing job descriptions and in recognising skills gaps.

Challenging established working practise

It is important to understand the processes involved within a clothing manufacturing environment and whilst no 2 businesses function in exactly the same manner, the basic principles are ever present. The key principal is to understand and control cost.

There was a move away from CMT type manufacturing several years ago as contracts were awarded to overseas manufacturing units on an FOB basis; this effectively meant that the manufacturer took total control of the process. The main problem with trading using the FOB method is that the costs are hidden and it is very difficult to negotiate a better price.

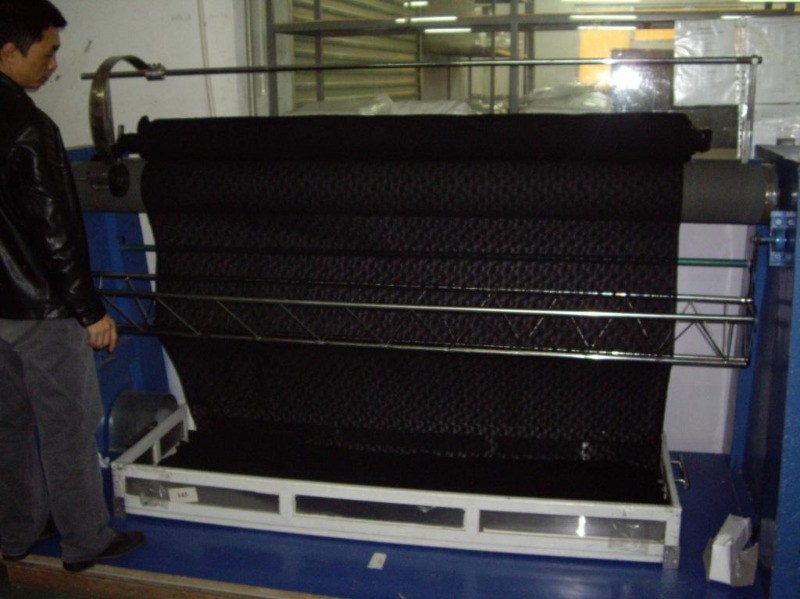

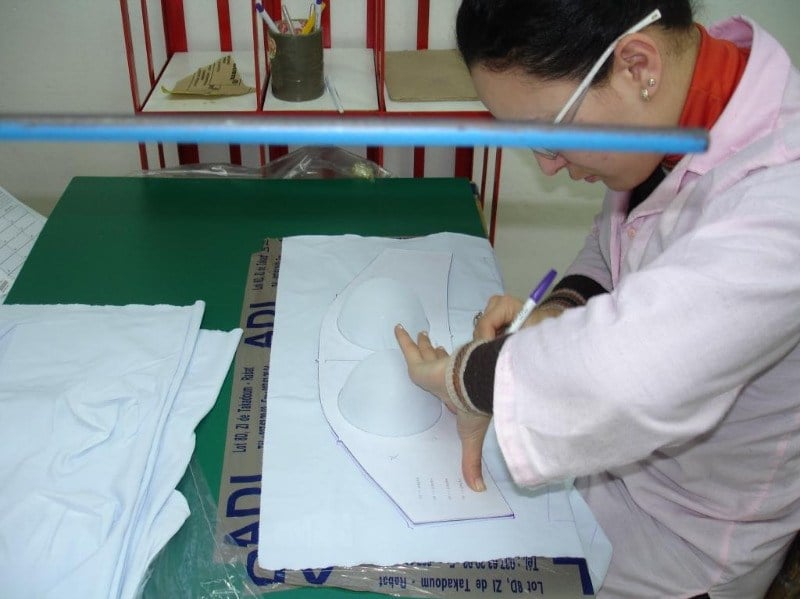

To be able to effectively challenge cost in the manufacturing base it is critical that you fully understand the process. It requires hands on working experience at each key stage. This is where Gradeplan can offer detailed and effective support; interpreting design sketches into production ready pattern patterns, costings, recommending optimum fabric widths, optimising the production and lay planning processes to ensure maximum raw material usage, creating all relavant size charts, fit logs, lay planning and production planning paperwork, ensuring that cutting room usage aligns itself with expected costed usage and initiating claims against fabric suppliers for non conformance.

We have many years experience working with clothing businesses of varying sizes each with their own unique way of working. Gradeplan will engage with your business and work with key members of staff to create a clear guide for all of your employees. In writing systems and procedures it is quite normal that current methods are challenged and as a result modified to ensure best practise is adopted.

When you bring new experienced staff into your business they often bring with them valuable new ways of working that could improve your efficiency and you have a duty to unlock this knowledge and record it.

In our experience the simpler the better; a good systems and procedures document will not try to recreate how your business functions but will simply record existing working practise in a logical, clear and standardised way. Presenting the information in this way will ensure your employees refer to and often improve a key working guide.

Each process will have the following information recorded;

- Purpose - brief description of process and why it is required

- Scope - describes area covered by procedure

- Responsibility - which members of staff are involved in process and who has direct responsibility

- Procedure - detailed elements of process

There is no substitute for a good induction programme with experienced members of staff guiding new employees; having your methods recorded and documented does not replace this, it underpins it.